Base Inventory Cooperation Strategy of Multi-parts with Supply-Hub

- Li Shuang-yan

- Zhang De-zhi

- Jin Fang-ping

Abstract

We investigate two stage supply chain optimization coordination with Supply-Hub operation mode for assemblymanufacturing enterprise. Because all parts delivery of all suppliers are integrated at Supply-Hub, all neededparts by the production line are selected, packaged and then sent to the manufacturer by Supply-Hub. Weapplied queuing theory and basic inventory strategy to model this system and derive the optimization solutionfor decentralized decision and centralized decision separately. Then coordination inventory strategy is obtainedby comparing decentralized decision and centralized decision. Due to inventory risk shifting from manufacturersto suppliers with Supply-Hub operation mode, backorder and holding cost subsidy contracts are used forcoordination that incites suppliers to set basic inventories in favor of whole supply chain operation costreduction. And numerical examples of three suppliers and one manufacturer are given to illustrate theeffectiveness of the coordination strategy and the condition to gaining Pareto improving for whole system withthe collaborative strategy.

- Full Text:

PDF

PDF

- DOI:10.5539/ijbm.v8n20p96

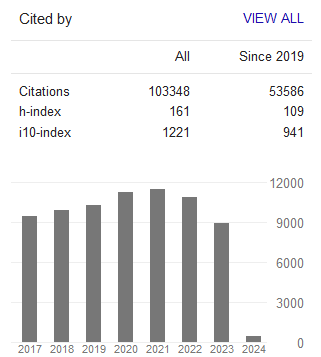

Journal Metrics

Google-based Impact Factor (2023): 0.86

h-index(2023): 152

i10-index(2023): 1168

Index

- Academic Journals Database

- AIDEA list (Italian Academy of Business Administration)

- ANVUR (Italian National Agency for the Evaluation of Universities and Research Institutes)

- Berkeley Library

- CNKI Scholar

- COPAC

- EBSCOhost

- Electronic Journals Library

- Elektronische Zeitschriftenbibliothek (EZB)

- EuroPub Database

- Excellence in Research for Australia (ERA)

- Genamics JournalSeek

- GETIT@YALE (Yale University Library)

- IBZ Online

- JournalTOCs

- Library and Archives Canada

- LOCKSS

- MIAR

- National Library of Australia

- Norwegian Centre for Research Data (NSD)

- PKP Open Archives Harvester

- Publons

- Qualis/CAPES

- RePEc

- ROAD

- Scilit

- SHERPA/RoMEO

- Standard Periodical Directory

- Universe Digital Library

- UoS Library

- WorldCat

- ZBW-German National Library of Economics

Contact

- Stephen LeeEditorial Assistant

- ijbm@ccsenet.org